1. How long time you have been in the forestry/logging business? How many hectares do you handle each year using machinery?

Our family settled in Scoggins Valley, Oregon, in the early 1900’s and five generations later, we still call it home. Since then, we have been active in both the agricultural and timber industries. We take pride in having 100 years of experience under our belts. In an average year, we work with approximately 25-30 different landowners with various projects.

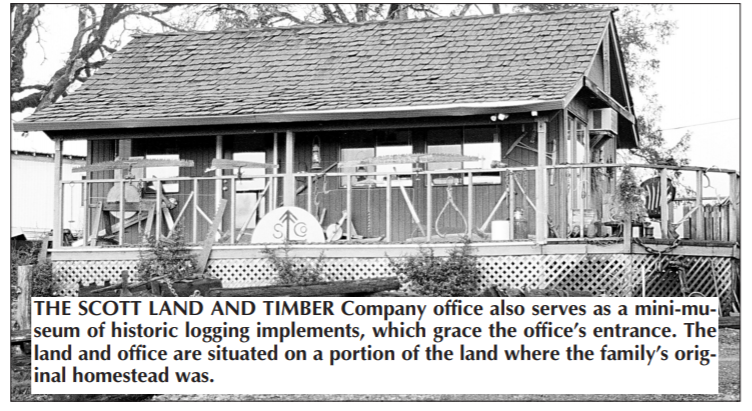

Mark Scott, President

Scott Land and Timber Co. Inc.

2. What are the main activities in your service offering?

Brushing, logging, road building, rock/ material delivery, culvert repair and installation, land clearing, and stump removal.

3. Why is stump removal required in the US forestry sector? Should it be more for sustainable forestry? What is the current attitude towards sustainable forestry or becoming more environmentally friendly?

Sustainability is all about balance. Balancing the need for forest products versus preservation and diversity is imperative. This balance is critical to the survival of forests and the prosperity of forest-dependent communities.Stump removal is a necessary process to keep our forests healthy and to promote regeneration. Many diseases plague forests deep within tree roots and can still spread from tree to tree. Removing diseased stumps encourages the health of surrounding trees and aids in new growth. Recycling the stumps is also a prevalent forestry practice. It grinds them for mulch, improves soil quality, and promotes re-growth and plant diversity. As loggers, we are stewards of the land, and we strive to protect and preserve it for our future generations to come.

4. How was deforestation and stump removal processed before you used the Dipperfox stump crusher?

Prior stump removal practices included pushing them over or pulling them out of the ground entirely; this process proved to be tedious and costly. It also created a problem of what to do with them once they were removed. Transporting large odd-shaped stumps is challenging, not to mention burning and dumping restrictions have made it even more difficult for contractors to get rid of the stumps. Stumps left in the ground take years to break down and decompose, impacting future replanting or land development projects.

5. How much is this service in demand?

Due to the devastating fires of 2020 and the Corona Virus, forestry product demand has reached a historical high. Stump grinding is the most cost-efficient, time-saving, eco-friendly way to totally remove stumps and get our forests cleaned up and replanted.

6. What was the cost of removing stumps before using Dipperfox?

Depending upon the type and size of stumps, it would take anywhere from 30 minutes to 1 hour to remove one stump. Add this with the hourly rate of the equipment being used could cost anywhere from $150-250 per hour. The cost to haul the stumps away also varies between truck and trailer hourly costs and dump fees, totaling $85-120 per hour.

7. What is the average size of the forest – how many trees/stumps per hectare?

It is hard to average the size of our forest projects. We have completed extensive and small jobs, including 5-acre plots, and managed private parcels up to 1000 acres during timber harvesting. In the short time of owning our Dipperfox, we have cleared approximately 4 acres of large diameter stumps in less than 8 hours.

8. Where did you hear about Dipperfox?

We discovered Dipperfox online through your website and Youtube.

9. What was your trigger to purchasing one?

We were impressed with the online videos and the quality of the product. The professional and knowledgeable communication we received from Joel Rang (Dipperfox Global Sales) secured our decision to purchase one.

10. How has it earned your Return On Investment? (ROI)

We have had great success in offering stump removal as an added service with our land clearing. Most customers are excited about taking full advantage of it. We are looking forward to becoming the exclusive dealer in the PNW and sharing this great tool with more people.

11. How efficient is it compared to previous methods?

It saves on operator wages, equipment hour rates, fuel, and machine repair costs. It is a more manageable system that puts less wear and tear on our excavators and other equipment, saving us money in the long run. We can see from a loose breakdown that it used to take 30 mins to dig one 36″ diameter stump. Each stump costs about $30.00 to remove when you factor in operator and fuel costs. The Dipperfox can grind 10 stumps of the same size in one hour, decreasing costs by 1000%, and pencils out to $3.00 per stump instead of $30.00

Share

Share