In the world of construction, efficiency and cost-effectiveness are key drivers of success. At Dipperfox, we understand this well, and our stump grinders are designed to meet these demands head-on. In this blog post, we’ll explore how Dipperfox stump grinders can revolutionize your construction projects, using a real-life case study from our hometown of Pärnu, Estonia.

How Dipperfox Stump Grinders Triple Your Savings on Construction Sites? A Practical Demonstration

To showcase the benefits of Dipperfox stump grinders, we conducted a practical test on a construction site in Pärnu, where a new football hall will be built within the next year.

We marked two areas, each 1,000 square meters in size, and with an equal volume of tree stumps.

In one area, we used traditional stump removal methods, while in the other, we deployed the Dipperfox stump grinder.

Stage One: The Time Factor

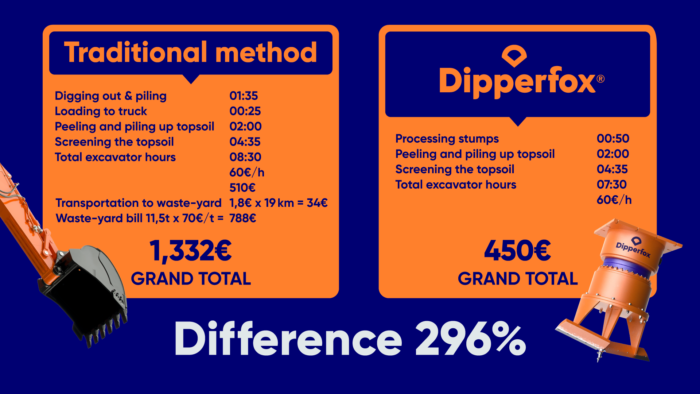

The first phase involved removing the stumps. In the traditional method, stumps were ripped out and piled up, taking a total of 1 hour and 35 minutes.

In contrast, the Dipperfox stump grinder processed the same area in just 50 minutes, leaving behind only fine wood chips.

This translates to a 90% reduction in excavator work time, significantly lowering fuel consumption and operator costs.

Stage Two: The Cost of Disposal

The next step highlighted one of the most expensive aspects of traditional stump removal: disposal.

The stumps from the traditional method needed to be loaded onto trucks and transported to a recycling plant, as they could not be left on-site. The 25 cubic meters of stumps required one truckload, costing 34 euros for transportation. However, the real expense came from the recycling plant, which charged 70 euros per ton. With a total weight of 11.42 tons, this added up to 788 euros.

In stark contrast, the Dipperfox method eliminated these costs entirely. The fine wood chips left behind required no transportation or recycling fees. In fact, by using a crusher bucket, you can further process the wood chips and roots, mixing them with the topsoil to enhance its quality as a fertilizer. This approach not only saves money but also benefits the environment by reducing CO2 emissions and diesel fuel consumption.

The Final Costs: Traditional Methods vs. Dipperfox

After completing both test areas, we tallied the total costs. For the Dipperfox site, the total excavator time was 7.5 hours, costing 450 euros.

On the other hand, the traditional method incurred significantly higher expenses. The total cost, including stump removal, transportation, and recycling, amounted to 1,332 euros. This means that using the Dipperfox stump grinder can save you up to three times the cost compared to traditional methods.

Conclusion: A Competitive Edge with Dipperfox

The results of our experiment are clear: Dipperfox stump grinders offer a more efficient, cost-effective, and environmentally friendly solution for stump removal on construction sites. By reducing work time, eliminating disposal costs, and enhancing the quality of the topsoil, Dipperfox provides a significant competitive advantage.

If your competitors haven’t discovered this yet, using Dipperfox could be the key to boosting your profitability in construction projects.

We hope you found this demonstration insightful. Stay tuned for more innovations and practical tips from Dipperfox!

Share

Share